When it comes to operating a fuel station, safety and compliance should always be a top priority. Regular inspections are essential to ensure that all equipment and facilities are in good working condition and meet the necessary safety standards. One effective tool that can help streamline the inspection process is a fuel station inspection checklist.

This guide will explore everything you need to know about these checklists, including why they are important, how to create them, and what to include.

What is a Fuel Station Inspection Checklist?

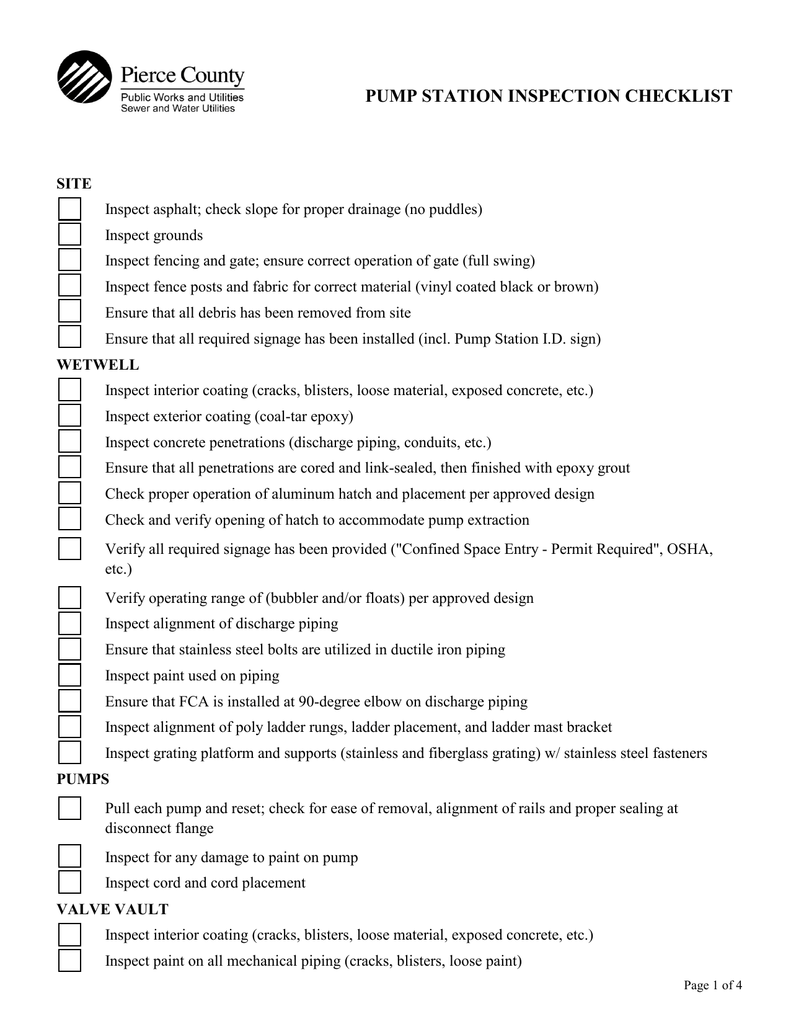

A fuel station inspection checklist is a comprehensive document that outlines all the areas and items that need to be inspected during a fuel station inspection. It serves as a guide for inspectors to ensure that every aspect of the fuel station is thoroughly examined and meets the required standards. These checklists are typically created in a format so that they can be easily filled out and carried out during inspections.

Why Should You Use a Checklist for Fuel Station Inspections?

There are several reasons why using a fuel station inspection checklist is beneficial. Here are some key advantages:

- Ensures thorough inspections: By following a checklist, inspectors can ensure that every area and item is inspected, reducing the risk of missing any potential safety hazards.

- Promotes consistency: Checklists help to standardize the inspection process, ensuring that all fuel stations are inspected using the same criteria and standards.

- Facilitates record-keeping: checklists serve as a record of inspections, making it easier to track past inspections, identify recurring issues, and address them promptly.

- Increases efficiency: With a checklist in hand, inspectors can complete inspections more efficiently, saving time and ensuring that all necessary inspections are conducted.

How to Create a Fuel Station Inspection Checklist

Creating a fuel station inspection checklist requires careful consideration of the specific requirements and regulations that apply to your fuel station. Here is a step-by-step guide to help you create an effective checklist:

1. Research Applicable Regulations

Start by researching the regulations and requirements set forth by relevant authorities, such as local authorities or industry-specific organizations. Familiarize yourself with the specific safety standards that need to be met during a fuel station inspection.

2. Identify Inspection Areas

List all the areas that need to be inspected during a fuel station inspection. This may include fuel dispensers, storage tanks, fuel lines, emergency shut-off systems, fire extinguishers, and more.

3. Break Down Inspection Areas into Specific Items

For each inspection area, break it down into specific items that need to be checked. For example, under the fuel dispensers area, you may have items such as nozzle condition, hose condition, dispenser calibration, etc.

4. Include Detailed Checkpoints

For each specific item, include detailed checkpoints that inspectors need to follow. These checkpoints should be specific and measurable to ensure consistency in inspections.

5. Add Space for Notes and Signatures

Leave space in the checklist for inspectors to make notes about any issues or observations during the inspection. Also, include a section for signatures to confirm that the inspection has been completed.

6. Format the Checklist for Printing

Once you have created the checklist, format it in a format. Consider using a table format for easy readability and space for handwritten notes.

Sample Fuel Station Inspection Checklist

Here is an example of a fuel station inspection checklist:

- Inspection Area: Fuel Dispensers

- Nozzle Condition: Check for any damage or leaks in the nozzle.

- Hose Condition: Inspect the condition of the fuel hose for any cracks or leaks.

- Dispenser Calibration: Verify that the dispenser is dispensing the correct amount of fuel.

- Emergency Stop Button: Test the emergency stop button to ensure it is functioning properly.

- Inspection Area: Storage Tanks

- Tank Level Gauge: Check the accuracy of the tank level gauge.

- Leak Detection System: Test the leak detection system to ensure it is operational.

- Tank Ventilation: Inspect the ventilation system to ensure proper airflow.

- Tank Labels: Check that all tanks are properly labeled with the correct fuel type.

- Inspection Area: Fuel Lines

- Fuel Line Condition: Inspect the condition of the fuel lines for any leaks or damage.

- Fuel Line Connections: Check that all connections are secure and free from leaks.

- Fuel Line Insulation: Verify that the fuel lines are properly insulated to prevent freezing.

Download the Checklist Template!

A fuel station inspection checklist is a valuable tool for ensuring safety and compliance in fuel stations. By following a checklist, inspectors can conduct thorough and consistent inspections, while also facilitating record-keeping and efficiency.

Whether you choose to create your checklist or use a ready-made template, incorporating this tool into your fuel station inspection process will help maintain a safe and compliant environment for both employees and customers.

Fuel Station Inspection Checklist Template Excel – Download